IIT Indore Develops Low-Cost Metal 3D Printing Technology for Global Manufacturing

For decades, 3D printing has carried the promise of transforming manufacturing. It’s been described as a revolution—one where ideas move from computer screens to tangible objects at lightning speed. Yet, in reality, much of this promise has remained locked behind high costs, especially when it comes to metal 3D printing.

For decades, 3D printing has carried the promise of transforming manufacturing. It’s been described as a revolution—one where ideas move from computer screens to tangible objects at lightning speed. Yet, in reality, much of this promise has remained locked behind high costs, especially when it comes to metal 3D printing. The machines are expensive, the materials are costly, and the expertise required is rare.

But now, a pioneering team of researchers at the Indian Institute of Technology (IIT) Indore has taken a decisive step forward. By creating a low-cost metal 3D printing technology, they have potentially changed the game not only for India but also for global industries struggling to democratize advanced manufacturing.

This breakthrough offers affordable access to additive manufacturing, allowing small businesses, startups, and even research labs to leverage a tool once reserved for high-end aerospace corporations or defense labs. Beyond affordability, it embodies a spirit of innovation that ties neatly into India’s vision of Atmanirbhar Bharat (Self-Reliant India).

This article explores the science, applications, challenges, and global impact of IIT Indore’s development—and why it could become a cornerstone of the next industrial era.

Table of contents

Understanding Metal 3D Printing

Before diving into IIT Indore’s contribution, it’s important to understand what makes metal 3D printing so valuable and challenging.

What is Metal 3D Printing?

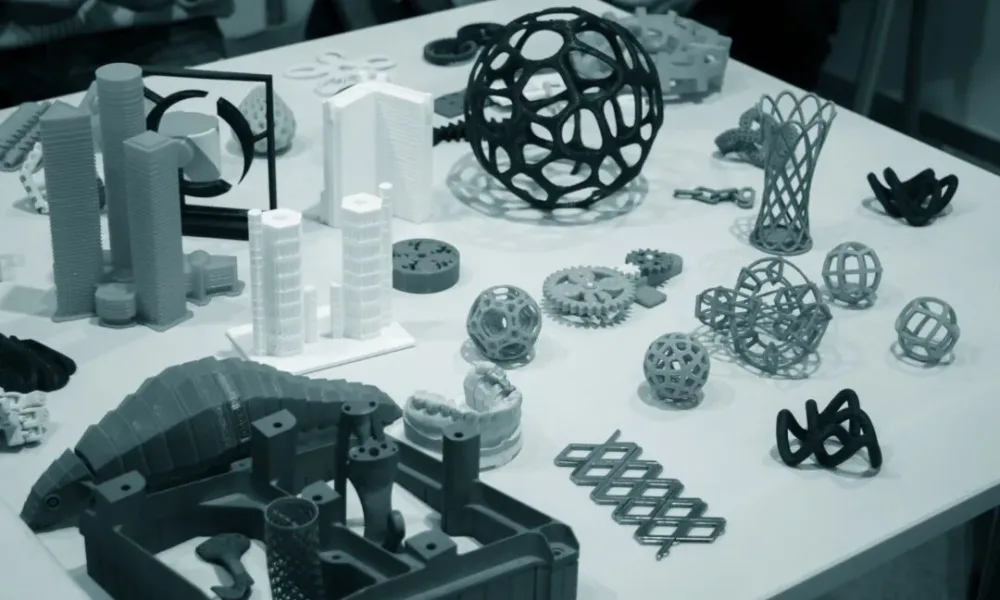

Metal 3D printing, or metal additive manufacturing, is the process of creating solid metal parts layer by layer from a digital design. Unlike plastic-based 3D printing (which has already gained wide popularity in prototyping and consumer applications), metal 3D printing deals with stronger, high-performance materials used in critical industries.

Why is it Important?

- Design Freedom: Traditional manufacturing limits what shapes can be made. Metal 3D printing allows for highly complex designs like lattice structures, lightweight aerospace parts, and internal cooling channels in engines.

- On-Demand Production: Instead of mass-producing and warehousing parts, industries can print them as needed.

- Sustainability: Less material waste compared to machining methods that cut away excess.

- Customization: Medical implants can be tailored to a patient’s anatomy. Automotive components can be engineered for specific performance needs.

The Cost Problem

Despite its potential, metal 3D printing is extremely expensive:

- Machines often cost $250,000 to $1 million or more.

- Specialized powders used as feedstock can cost several thousand dollars per kilogram.

- Maintaining controlled environments (lasers, inert gases, sealed chambers) further drives up expenses.

This has kept metal additive manufacturing out of reach for smaller industries and research institutes—until now.

The IIT Indore Breakthrough

1. The Technology

Researchers at IIT Indore have developed a metal 3D printing process that reduces costs dramatically. Instead of relying on costly laser-based powder bed systems, they used a method known as Wire Arc Additive Manufacturing (WAAM).

WAAM uses a welding arc as a heat source and standard metal wires as feedstock. By combining this with robotic precision and computer-aided design (CAD), metal structures can be built up layer by layer at a fraction of traditional costs.

2. Key Features

- Affordability: Uses welding-grade wire instead of expensive metal powders.

- Accessibility: Relies on widely available arc welding equipment, already common in many industries.

- Scalability: Capable of building both small components and large structures.

- Flexibility: Compatible with materials like steel, aluminum, and potentially advanced alloys in the future.

3. Cost Comparison

- Traditional laser-based metal 3D printer: ₹1–2 crore ($150,000–250,000+).

- IIT Indore’s WAAM setup: a fraction of that cost, potentially under ₹20–30 lakh ($25,000–35,000), depending on the configuration.

This is a 10x reduction in cost, making it feasible for SMEs, universities, and defense research centers.

Applications Across Industries

The impact of affordable metal 3D printing is vast. Here are some industries that stand to gain the most:

1. Aerospace

- Lightweight Components: Aircraft parts printed with lattice structures reduce fuel usage.

- On-Demand Replacement: Spare parts for planes can be produced locally, minimizing delays.

- Cost Savings: WAAM can cut material wastage by over 70%.

2. Automotive

- Prototyping: Car manufacturers can test designs faster and cheaper.

- Performance Parts: Customized exhaust systems, engine blocks, and lightweight chassis elements.

- Sustainability: Lower emissions by reducing the need for overseas supply chains.

3. Healthcare

- Patient-Specific Implants: Hip, knee, or jaw implants can be designed exactly for an individual.

- Surgical Tools: Customized instruments that improve surgical precision.

- Prosthetics: Lightweight, affordable designs for wider accessibility.

4. Defense & Security

- Self-Reliance: Defense forces can print critical spare parts in-house instead of relying on imports.

- Rapid Deployment: Quick production of replacement parts in remote or conflict zones.

- Innovation: Development of advanced weapons systems with lighter and stronger parts.

5. Energy & Infrastructure

- Renewable Energy: Custom turbine blades for wind or hydro power.

- Oil & Gas: Corrosion-resistant, complex parts for pipelines.

- Construction: Large-scale metal structures printed directly at sites.

The accessibility of this technology could help India reduce imports, strengthen supply chains, and boost local manufacturing capacity.

Global Relevance

The race for metal 3D printing dominance has been ongoing worldwide:

- United States: Companies like GE have invested billions in metal additive manufacturing, particularly for jet engines.

- Germany: Renowned for precision engineering, German firms lead in high-end 3D printing solutions.

- China: Scaling rapidly, with government-backed initiatives to integrate 3D printing across industries.

Yet, in all these cases, cost remains a limiting factor. IIT Indore’s innovation provides an affordable alternative that could appeal to not only India but also other developing nations seeking industrial independence.

This positions India as a global hub for cost-effective additive manufacturing solutions.

Challenges to Overcome

Every breakthrough comes with its hurdles. For IIT Indore’s technology, the following challenges must be addressed:

- Surface Finish & Precision

WAAM parts sometimes require post-processing (like CNC machining) to achieve the smoothness needed for aerospace or medical applications. - Material Limitations

While steel and aluminum are well-suited, advanced materials like titanium and superalloys may require further refinement. - Standardization

Industries like aerospace have strict certification requirements. The new technology will need to undergo rigorous testing to meet global standards. - Awareness & Training

Widespread adoption requires trained engineers who understand both design and production aspects of additive manufacturing. - Scaling Up

Moving from lab prototypes to industrial-scale production requires significant investment and partnerships.

Despite these challenges, the direction is clear: IIT Indore’s system could act as a stepping stone to mass adoption.

Strategic Value for India

This innovation ties directly to India’s national priorities:

- Atmanirbhar Bharat: Reduces dependency on foreign technologies.

- Make in India: Encourages local production and manufacturing.

- Startup Ecosystem: Affordable 3D printing empowers entrepreneurs to experiment and innovate.

- Defense Independence: Strengthens India’s ability to maintain and modernize its defense systems.

The economic ripple effect could be enormous. If small industries adopt this technology widely, India could see an explosion of localized, sustainable manufacturing.

Sustainability & Environmental Impact

Beyond economics, the environmental case for low-cost metal 3D printing is strong:

- Reduced Waste: Traditional machining wastes up to 80% of material; WAAM uses only what’s needed.

- Local Production: Cuts carbon emissions tied to global supply chains.

- Recycling Potential: Scrap metal could be repurposed as feedstock.

This aligns with India’s and the world’s goals for sustainable industrial development.

The Future of Low-Cost Metal 3D Printing

Looking forward, several possibilities emerge:

- Integration with AI: AI could optimize printing parameters in real time, ensuring quality.

- Robotics & Automation: Fully automated facilities producing components 24/7.

- Hybrid Manufacturing: Combining 3D printing with traditional machining for best results.

- Decentralized Factories: Smaller units spread across regions, reducing dependence on large plants.

- Global Collaborations: Partnerships with other developing nations for shared growth.

In the long run, this could make 3D printing as common as CNC machining.

Conclusion

The low-cost metal 3D printing technology from IIT Indore is more than an academic success—it’s a practical revolution. By drastically reducing costs and making the technology accessible, the institute has paved the way for democratized innovation.

From aerospace to healthcare, defense to renewable energy, the applications are nearly limitless. If scaled effectively, this could place India at the forefront of affordable, sustainable, and high-impact manufacturing.

In a world where innovation often feels exclusive, this development offers a rare chance to ensure technology serves everyone—not just the privileged few.

Innovation, Sustainability & Technology Shaping a Better Future

If this breakthrough in 3D printing inspired you, here are more impactful reads that highlight how technology, innovation and human effort are transforming industries and improving lives globally:

• Solar Minigrid Illuminates Goma, DRC – A powerful example of how technological innovation brings clean energy, safety, and opportunity to remote communities.

• Iceland Sets Historic Renewable Energy Record in 2025 – A milestone achievement showing how sustainable engineering can help build a cleaner future.

• Scientists Make Magic State Breakthrough After 20 Years – A fascinating scientific breakthrough that could transform the future of computing and advanced materials.

Looking for Words That Encourage Innovation, Progress & Possibility?

Positive Attitude – Quotes that spark vision, optimism, and belief in human potential.

The Positivity Collective

The Positivity Collective is a dedicated group of curators and seekers committed to the art of evidence-based optimism. We believe that perspective is a skill, and our mission is to filter through the noise to bring you the most empowering wisdom for a vibrant life. While we are not clinical professionals, we are lifelong students of human growth, devoted to building this sanctuary for the world.